Steel inspections often involve costly methods. Spark identification is a simple way to reduce these expenses effectively.

The spark test is a cost-effective steel inspection method. It identifies steel types by examining sparks generated during grinding.

Understand how spark tests reduce costs and why they're a reliable identification method.

What is the purpose of using a spark test on a piece of steel?

Spark tests solve inspection challenges by quickly identifying steel grades without expensive equipment.

Spark tests allow rapid identification of steel grades by examining the visual properties of sparks produced.

How does the spark test work?

The spark test works by grinding a steel sample against an abrasive wheel. This process produces sparks with unique shapes and colors. These sparks reveal the material's composition and grade.

Advantages of Spark Testing:

| Feature | Benefits |

|---|---|

| Speed | Results in seconds |

| Cost-Effectiveness | No need for expensive tools |

| Simplicity | Requires minimal operator skill |

While efficient, spark tests are best suited for preliminary identification. For precise analysis, use chemical testing.

What is the identification system used to identify steel?

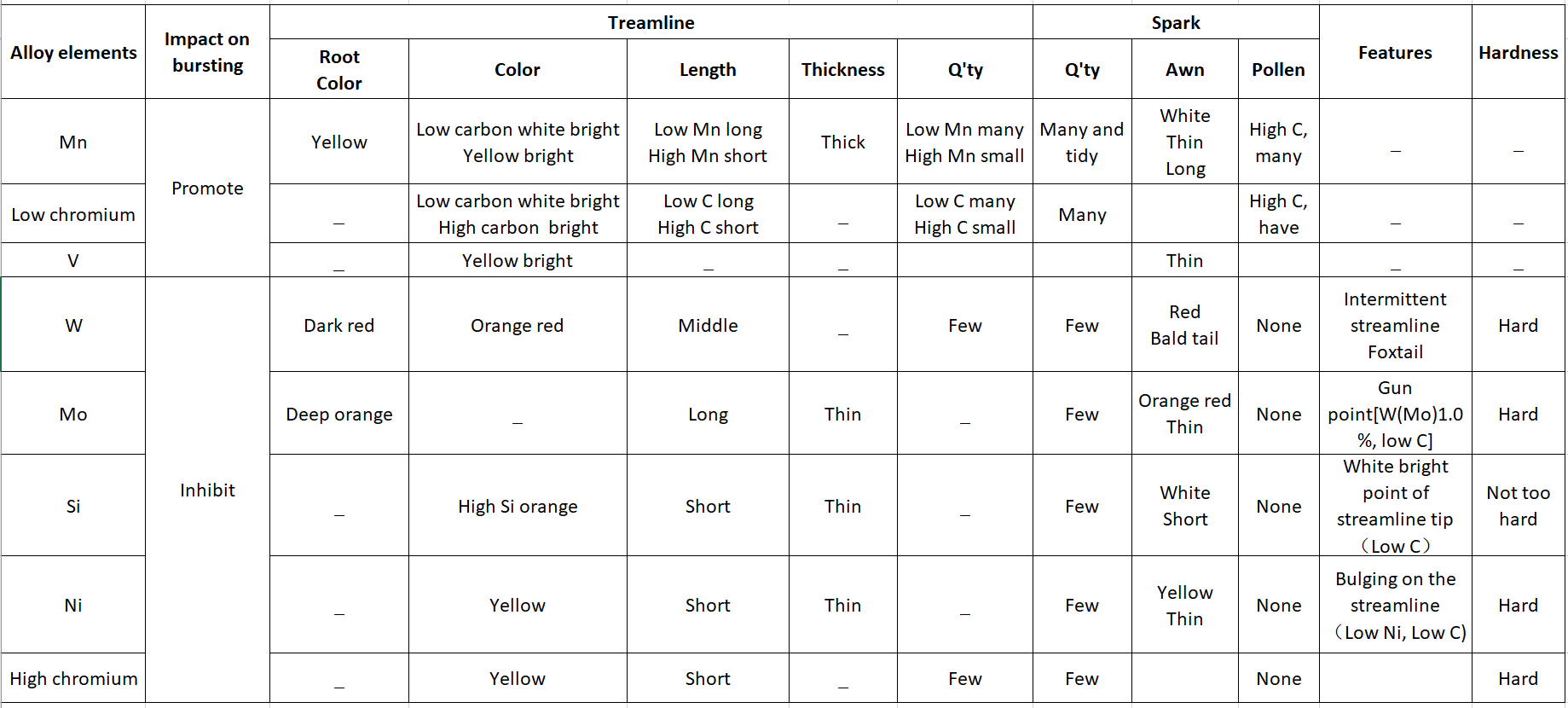

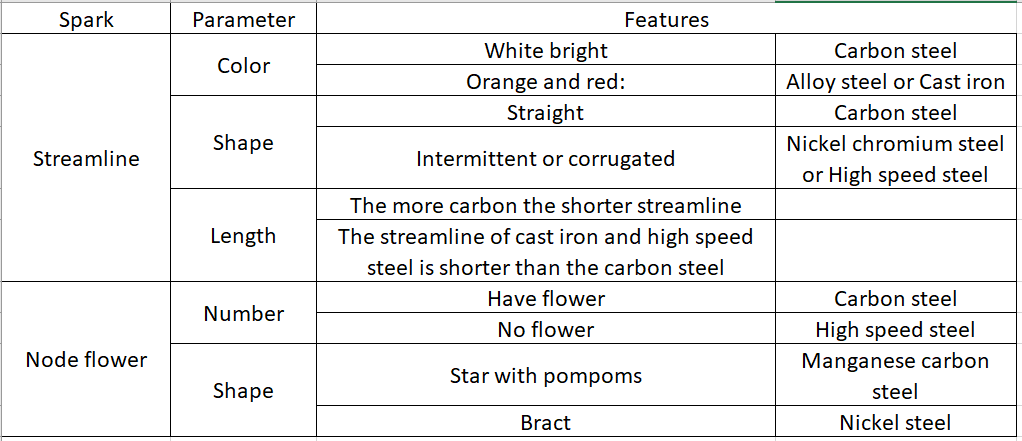

Steel identification systems rely on spark patterns to differentiate alloys. Each steel grade emits distinct spark shapes and bursts.

Spark patterns1 create a visual signature that correlates to specific steel alloys or carbon contents.

Comparing visual and chemical identification systems

The spark identification system is practical for low-budget, quick assessments. However, chemical analysis provides definitive data.

Key Differences Between Systems:

| Method | Application | Cost |

|---|---|---|

| Spark Identification | Quick alloy assessment | Low |

| Chemical Testing | Precise composition analysis | High |

Using spark testing as a first step minimizes costs while reserving detailed chemical analysis for critical cases.

What characteristic of the spark helps in identifying the metal?

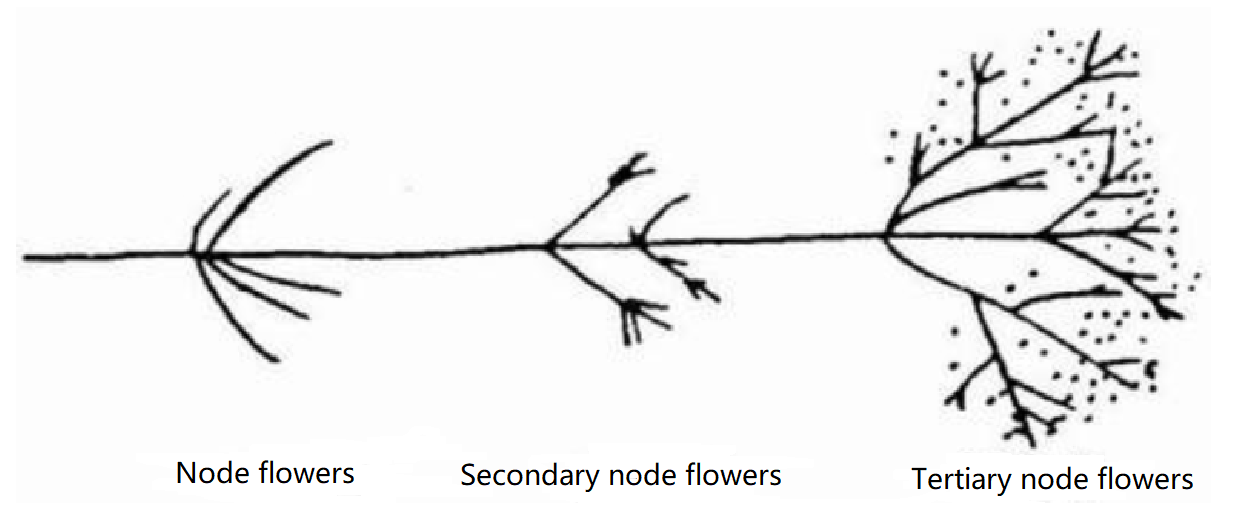

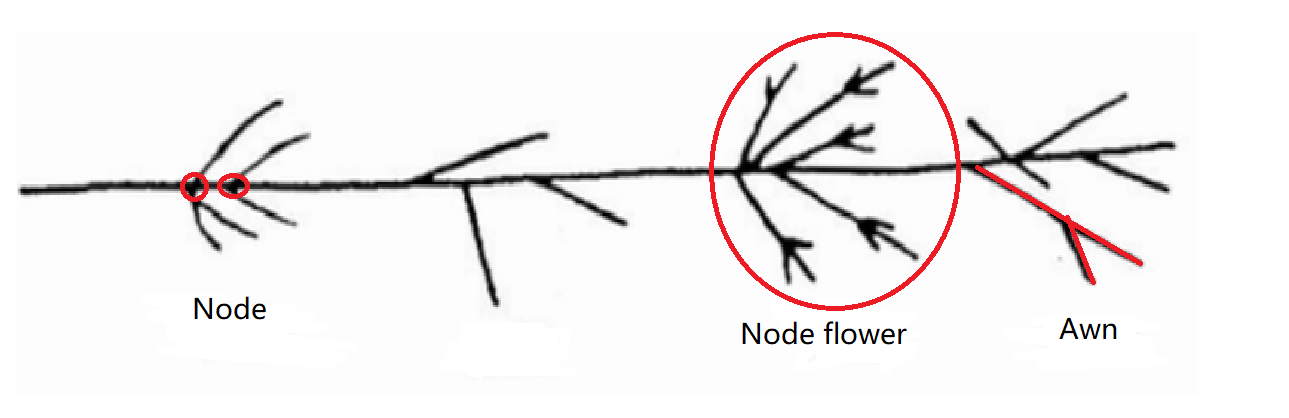

The shape, length, and color of sparks help determine steel types. High-carbon steels produce long, branching sparks, while low-carbon steels create shorter, simpler sparks.

Visual characteristics of sparks provide clues about carbon content and alloy elements in steel.

Breaking down spark characteristics

Each metal creates sparks with distinct visual properties. For example:

- Carbon Steel: Bright, long sparks with star-like bursts.

- Stainless Steel: Dull, red sparks with minimal bursts.

- High-Speed Steel: Dense, short sparks.

Understanding Spark Features:

| Spark Feature | Metal Type Examples |

|---|---|

| Long Bright Sparks | High-Carbon Steel |

| Short Red Sparks | Stainless Steel |

| Dense Sparks | High-Speed Steel |

Interpreting these features requires experience, but proper training simplifies the process.

What is the purpose of the spark test?

The spark test reduces costs by eliminating the need for advanced tools in preliminary steel identification.

Spark tests offer an economical solution for steel classification, making them valuable in industrial quality control.

The role of spark tests in the steel industry

The spark test helps industries quickly sort and identify steel types. This is especially useful in sorting scrap, verifying materials, and conducting routine checks.

How Spark Tests Save Costs:

| Scenario | Benefits |

|---|---|

| Scrap Sorting | Reduces misclassification |

| Material Verification | Prevents shipment delays |

| Routine Quality Control | Saves time and money |

By using spark tests as a preliminary tool, manufacturers minimize expenses while maintaining quality assurance2.

Conclusion

The spark identification method reduces inspection costs through simplicity, speed, and reliability, making it a practical choice for industrial applications.